History

History

Originally established in 1975 as the "Department of Ceramics and Glass," the department underwent several name changes to reflect its evolving academic focus. In 1983, it was officially renamed the Department of Ceramic Engineering, followed by another change in 2000 to the Department of Ceramics and Materials Engineering. In 2002, it adopted its current name, the Department of Materials Science and Engineering.

In 2003, the graduate program was launched, offering a Master’s degree in Materials Science and Engineering to equip students with the necessary knowledge and skills for professional advancement. In 2010, the department relocated to a new building on the Bajia Campus.

-

1975Department of Ceramics and GlassOriginally established in 1975, the Department was called the "Department of Ceramics and Glass.

-

1983Department of Ceramic EngineeringIn 1983, the Department of Ceramics and Glass was officially renamed Department of Ceramic Engineering.

-

2000Department of Ceramics and Materials EngineeringIn 2000, the Department of Ceramic Engineering was officially renamed Department of Ceramics and Materials Engineering.

-

2003Department of Materials Science and EngineeringIn 2002, the Department of Ceramics and Materials Engineering was officially renamed Department of Materials Science and Engineering.

-

2003The graduate school is foundedIn 2003, the graduate School is launched, offering Masters degrees in Materials Science and Engineering. The master program will enable students the needed knowledge to enhance their skills.

-

2010Move to the new campusThe Department was moved the new building in Bajia Campus in 2010.

The department aims to foster research and innovation in the following key areas.

Semiconductor materials: memristor; gate oxides and metal gates; ion implantation; transparent conductive thin film.

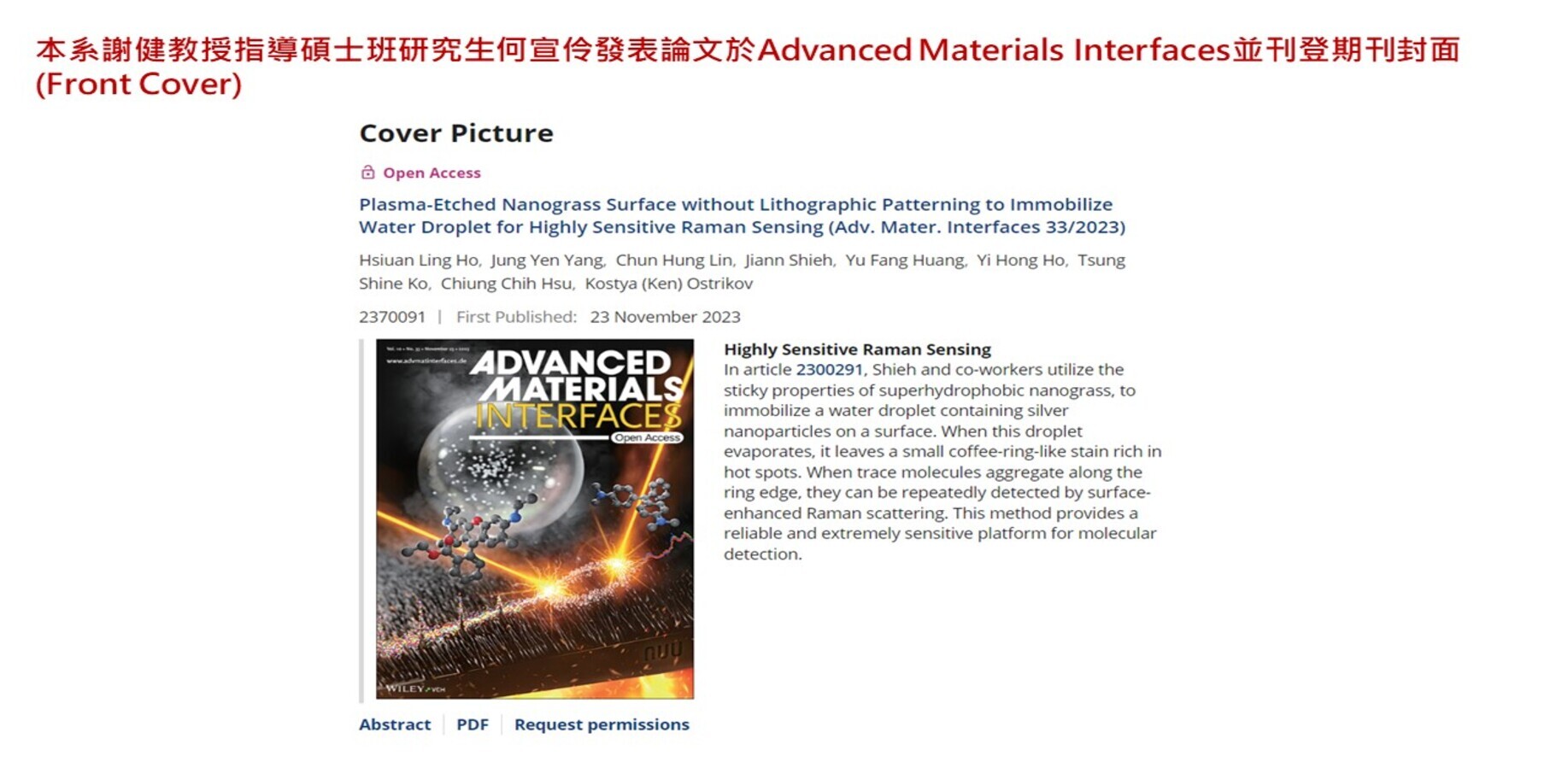

Nanomaterials: nanostructures such as nanograss, nanowires, nanopillars; AAO-assisted nanostructures; SERS; solar cells.

Glass materials: molding glass; glass fiber; touching panel; encapsulation glass; strengthened glass; IR transmitting glass.

Ceramic materials: electronic passive components; piezoelectric ceramics; biomedical ceramics.

Thin film process: super-hard alloy coating; HIPIMS thin film.

Polymer materials: solar cells; resistive memory; organic vehicle.

Process modeling and simulation: steel and aluminum alloy process; float glass manufacturing; powder bed fusion; laser cladding.

Metal materials: aluminum alloy casting; powder metallurgy; conductive paste.